- Home

- Products

- Mining Machinery Accessories

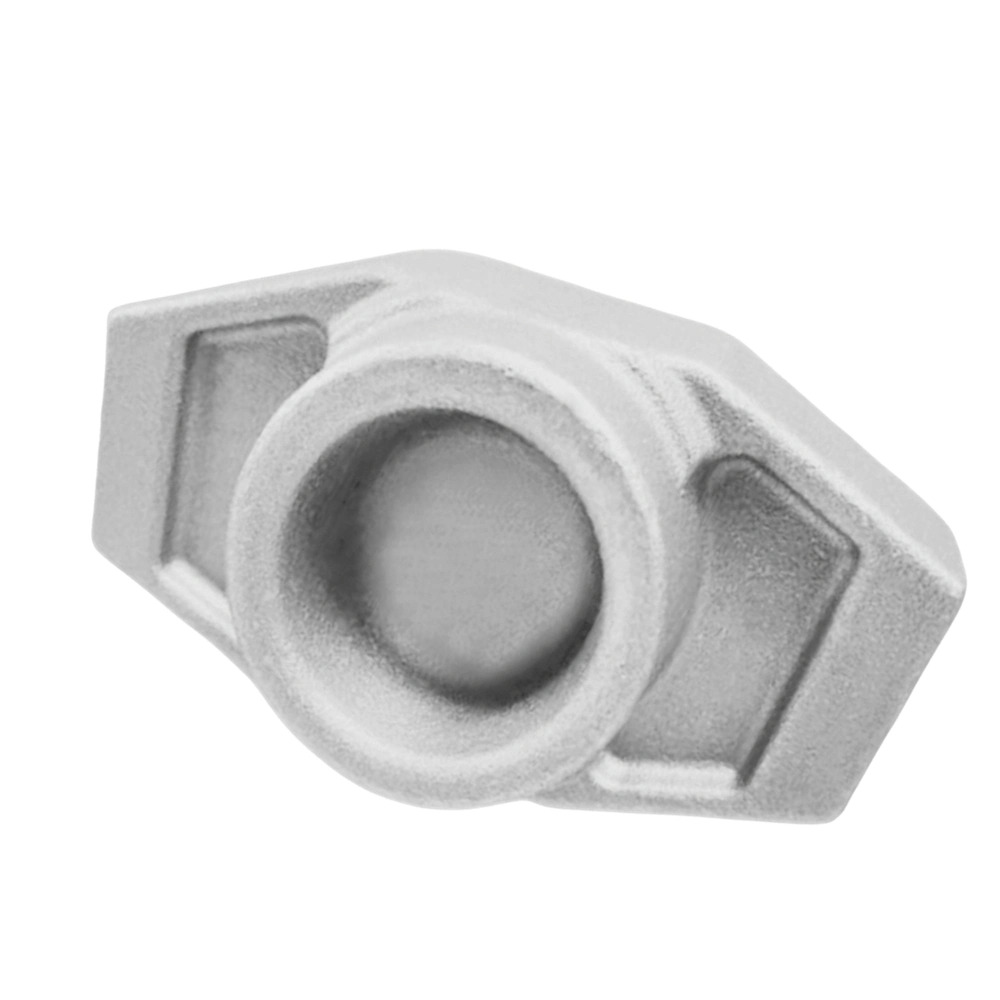

- Mining Machine Machinery Equipment Spare Part Attachment Forged Alloy Steel 3 Claws Cap

Mining Machine Machinery Equipment Spare Part Attachment Forged Alloy Steel 3 Claws Cap

Application: Machinery Parts

Material: Steel

Standard: GB

Certification: ISO 9001:2008

Weight: 1-20kgs

MOQ: 1000 PCS

Basic Info.

| Transport Package | Standard Packing |

| Specification | steel |

Product Description:

Products features:

Name: Mining Machine Machinery Equipment Spare Part Attachment Forged Alloy Steel 3 Claws Cap

Material: steel

Processing: forging

| Process | Sand Casting | |

| Material | Grey Iron, Ductile Iron, Carbon Steel | |

| Weight | 0.1Kg~20Kg | |

| Testing instrument | composition testing | Spectrometer, Metallographic microscope |

| Performance testing | Hardness tester, Tensile testing machine | |

| Size Measuring | Vernier Caliper, Depth Caliper, feeler gauge, Thread Gauge, Height Gauge | |

| Roughness | Ra1.6~Ra6.3 | |

| Machining Equipment | CNC Center, CNC Machines, Turning, Drilling, Milling, Boring machine, Grinding Machines | |

| Wire EDM, Laser Cutting&Welding, Plasma Cutting &Welding, EDM etc. | ||

| Quality control | Sampling inspection of raw materials and semi-finished products, 100% Inspection of finished products | |

| Surface Treatment | Sand Blast, Painting, Powder Coating, Galvanized, Hot Galvanized | |

| Production Capacity | 60000T / Years | |

| Lead Time | Normally 30 - 45 Days. | |

| Payment Terms | T/T, L/C | |

| Material Standard | ASTM, AISI, DIN, BS, JIS, GB, | |

| Certification | ISO9001:2008, IATF16949:2016 | |

Products Quality Control

We insist that the survival of the company should depend on the products quality i continuous improvement, without which we cannot survive for long.

Our product quality control system:

Quality control involves the inspection and control of incoming materials, production process and finished products.

1. Firstly, metallurgical microscope analysis is performed on randomly sampled incoming materials to ensure that the chemical composition meets the production requirements.

2. Then, during the production process, there are QC personnel to conduct timely spot checks to ensure that the product is free of defects during the manufacturing process and to coordinate and handling of any abnormal quality issues that may arise.

3. The final step in the production process is a magnetic particle detector for metal parts to detect hidden cracks or other defects.

4. All the finished metal parts is sampled in proportion and sent to the laboratory for various mechanical property tests and dimensional measurements, and the surface quality is manually 100% inspected.

Quality management system of the organization

We strictly carry out system management in accordance with iso9001 and ts16949 quality standards. And 5S lean production management is implemented on the production site.The certification we have passed and the pictures of production management site are as follows:

Our Service:

A. Customized and Standard Manufacturing Service

B. A variety of Manufacturing Process Integration

C. Quality and Delivery Time Guaranteed

D. Effective Communication Ability

FAQ:

Q: Are you a trading company or a manufacturer?

A: Obviously we are a manufacturer of forging products, casting products and also have a high level of machining capabilities.

Q: What series products do your have?

A: We are mainly engaged in forming processing of ferrous metals, including processing by casting, forging and machining. As you know, such machinery parts can be observed in various industries of equipment manufacturing.

Q: Do you provide samples? is it free?

A: Yes, we commonly provide samples according to the traditional practice, but we also need customers to provide a freight pay-by-account number to show mutual sincerity of cooperation.

Q: What is your minimum order quantity?

A: Yes, we require all international orders to have an minimum order quantity. The quantity is up to the exact products feature or property such as the material, weight, construction etc.

English

English Français

Français Español

Español Deutsch

Deutsch Русский

Русский العربية

العربية