- Home

- Products

- Mining Machinery Accessories

- China Construction Machinery Part Spare Parts Forged Metal Core of Rubber Track

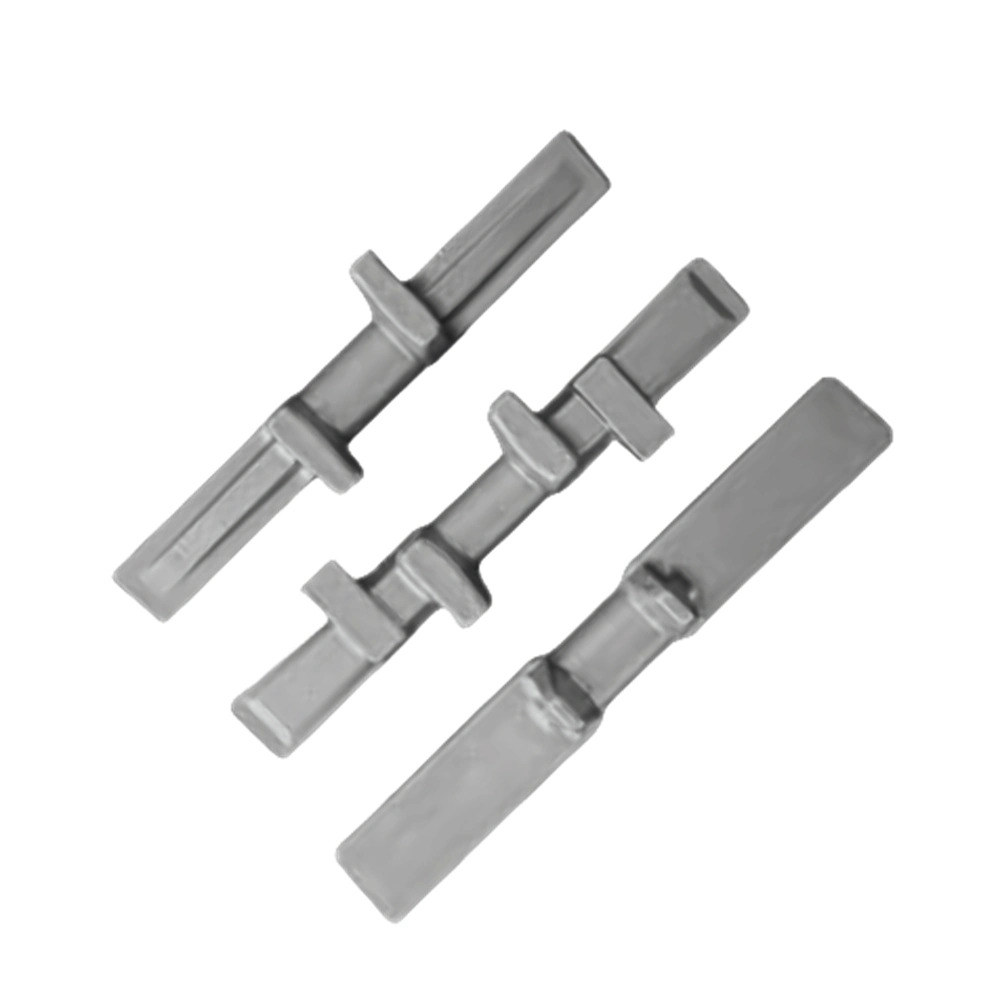

China Construction Machinery Part Spare Parts Forged Metal Core of Rubber Track

Processing Object: Metal

Molding Style: Forging

Molding Technics: Pressure Casting

Application: Agricultural Machinery Parts

Material: Steel

Heat Treatment: Tempering

Basic Info.

| Model NO. | HM2021 |

| Surface Treatment | Sand Blasting |

| Forging Tolerance | +/-0.5mm |

| Standard | GB |

| Certification | ISO 9001:2000 |

| Steel Specification | 45# Steel |

| Weight | 1-10kgs |

| Hardness | 48-51HRC |

| Service | OEM ODM |

| Transport Package | Stand Export Packing |

| Specification | HM2021 |

| Production Capacity | 5000t/ Year |

Product Description:

Products features:

Name: China Construction Machinery Part Spare Parts Forged Metal Core of Rubber Track

Material: 45#

Weight: From .1kg-10kg

Packing: Stand Export Packing

Min order: 1000pcs

Customized production is available as your drawings or sample.

| Process | Die Forging | |

| Material | Stainless Steel, Carbon Steel, Alloy Steel | |

| Weight | 0.1Kg~20Kg | |

| Heat Treatment | Quenching, Annealing, Tempering, Normalizing, Quenching and Tempering | |

| Testing instrument | composition testing | Spectrometer, Metallographic microscope |

| Performance testing | Hardness tester, Tensile testing machine | |

| Size Measuring | CMM, Micrometer, Vernier Caliper, Depth Caliper, feeler gauge | |

| Thread Gauge, Height Gauge | ||

| Roughness | Ra1.6~Ra6.3 | |

| Machining Equipment | CNC Center, CNC Machines, Turning, Drilling, Milling, boring machine, Grinding Machines | |

| Wire EDM, Laser Cutting&Welding, Plasma Cutting &Welding, EDM etc. | ||

| Quality control | Sampling inspection of raw materials and semi-finished products, 100% Inspection of finished products | |

| Surface Treatment | Shot Blast, Powder Coating, Polishing, Galvanized, Chrome Plated | |

| Production Capacity | 60000T / Years | |

| Lead Time | Normally 30 - 45 Days. | |

| Payment Terms | T/T, L/C | |

| Material Standard | ASTM, AISI, DIN, BS, JIS, GB, | |

| Certification | ISO9001:2008, IATF16949:2016 | |

Products Quality Control

Quality control involve the inspection and control of incoming materials, production processes, and finished products.

The quality control process includes:

1. First of all, the incoming raw materials with random sampling are analyzed by metallographic microscope to ensure that the chemical composition meets the production requirements.

2. Then In the production process, there are QC staffs timely sampling ensure that the products are free of defects in the manufacturing process, and to coordinate and handle any abnormal quality issues may be occurred.

3. The final step of production process is magnetic particle flaw detector of the metal parts to detect it's hidden crack or other defects.

4. All the finished metal parts is sampled in proportion and sent to the laboratory for various mechanical performance tests and size measurement, and the surface quality is manually 100% inspected.

Quality Management System Control:

We strictly carry out system management accordance with iso9001 and ts16949 quality standards. And 5S lean production management is implemented on the production site.

The production management site as following:

Our Advantages:

Technology

We have a complete production process and equipment research and development capabilities for ferrous metals forming. More than 25 years of production experience in forging equipment and casting equipment manufacturers, make us more thoroughly get all the performance of each equipment. One-third of our company's employees are technician and R&D personnel, ensuring that high-quality products are produced with high efficiency.

Service

We can provide custom and standard manufacturing services with multiple manufacturing process integrations. The quality and delivery of products can be fully guaranteed, and the ability to communicate quickly and effectively.

Culture

The unique corporate culture can give full play to the potential of individuals and provide a strong vitality for the sustainable development of the company.

Social responsibility

Our company strictly implements low-carbon environmental protection, energy-saving and emission-reduction production, and is a benchmark enterprise in local region.

FAQ:

Q: Are you a trading company or a manufacturer?

A: Obviously we are a manufacturer of forging products, casting products and also have a high level of machining capabilities.

Q: What series products do your have?

A: We are mainly engaged in forming processing of ferrous metals, including processing by casting, forging and machining. As you know, such machinery parts can be observed in various industries of equipment manufacturing.

Q: Do you provide samples? is it free?

A: Yes, we commonly provide samples according to the traditional practice, but we also need customers to provide a freight pay-by-account number to show mutual sincerity of cooperation.

Q: Is OEM available?

A: Yes, OEM is available.

Q: What's your quality guarantee?

A: We insist that the survival of the company should depend on the products quality continuous improvement, without which we cannot survive for long. We carry out strictly product quality control for every process from incoming materials, production process to finished products via advanced detection instrument and equipment. We also invite independent third parties to certify our quality and management systems. Till now we have passed ISO/TS16949 and SGS certification.

Q. How about the Packing?

A: We usually use the iron box, or wooden case, also it can be customized according to customer's demands.

Q: What is your minimum order quantity?

A: Yes, we require all international orders to have an minimum order quantity. The quantity is up to the exact products feature or property such as the material, weight, construction etc.

English

English Français

Français Español

Español Deutsch

Deutsch Русский

Русский العربية

العربية